Introduction

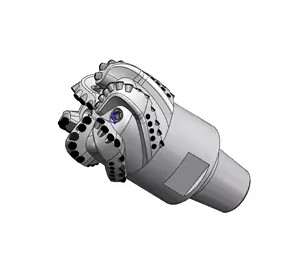

Electrical discharge machining (EDM) is a crucial technology in manufacturing PDC bits. This technique allows for the creation of complex geometries that are essential for optimal drilling performance. This article discusses the principles of EDM and its advantages in producing high-precision PDC bits.

Principles of Electrical Discharge Machining

EDM works by eroding material from a workpiece using electrical discharges. A conductive tool electrode is brought close to the workpiece, creating a spark that removes material. This process allows for intricate designs to be formed without applying mechanical force. The precision of EDM is particularly beneficial for creating the detailed features required in PDC bits.

Advantages of EDM in PDC Bit Manufacturing

The use of EDM in PDC bit manufacturing offers several advantages. First, it enables the production of intricate shapes that traditional machining cannot achieve. Second, EDM provides high precision, ensuring that each bit meets strict specifications. Additionally, the process minimizes tool wear, which results in lower production costs. Finally, EDM can work with hard materials, making it ideal for PDC manufacturing.

Design Considerations for EDM

When using EDM for PDC bit manufacturing, specific design considerations must be taken into account. The choice of electrode material affects the machining speed and finish quality. Additionally, the gap between the electrode and the workpiece must be carefully controlled to ensure optimal erosion rates. Understanding the properties of the PDC material is also critical for successful machining.

Applications of EDM in PDC Bits

EDM is used in various applications within the PDC bit manufacturing process. It is commonly applied to create intricate cooling channels, which enhance thermal management during drilling. EDM can also be used to fabricate the complex shapes of cutting edges that improve penetration rates. Furthermore, EDM helps achieve the fine tolerances required for the precise fit of components.

Challenges in EDM

While EDM offers numerous benefits, it also presents challenges. The process can be slower than traditional machining methods, leading to longer production times. Additionally, the high cost of equipment can be a barrier for smaller manufacturers. Operators must also be skilled in using EDM technology to achieve the desired outcomes. Addressing these challenges is essential for maximizing the benefits of EDM in PDC manufacturing.

Conclusion

High-precision electrical discharge machining is vital for producing effective PDC bits. Its ability to create complex geometries and ensure precision makes it a preferred choice in the industry. As manufacturing demands continue to evolve, advancements in EDM technology will further enhance PDC bit performance and efficiency. The future of drilling relies on the continued innovation of machining techniques like EDM.