Introduction

Selecting the right drill bit for specific geological environments is crucial for successful drilling operations. Different formations present unique challenges, and understanding these challenges is essential for effective bit selection. This article outlines key criteria for selecting drill bits based on geological conditions, including types of formations, bit types, and operational considerations.

Understanding Geological Conditions

Geological formations can vary significantly, including soft formations, hard rock, and abrasive materials. Each type of formation affects drilling performance differently. Soft formations, such as clay or sand, often require drill bits with specialized cutting geometries to prevent excessive penetration rates and ensure efficient removal of cuttings. In contrast, hard rock formations, like granite or basalt, demand drill bits made from durable materials, such as tungsten carbide or polycrystalline diamond (PDC), to withstand the abrasive nature of the material.

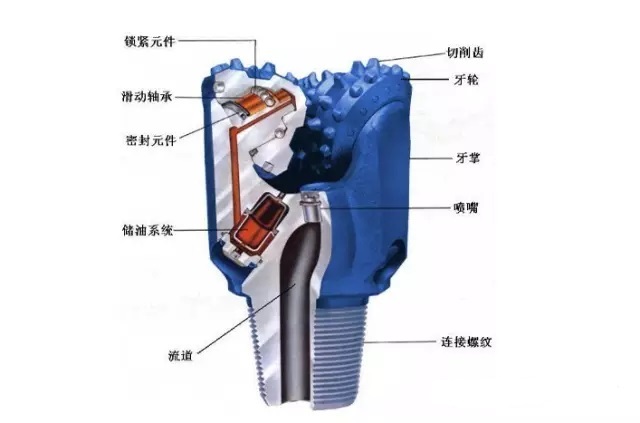

Bit Type Considerations

Different bit types are suited for specific geological environments. For soft formations, drag bits or fixed cutter bits are often used. These bits utilize a series of blades to cut through soft material efficiently. However, for harder formations, roller cone bits or PDC bits are typically more effective. Roller cone bits can adapt to varying hardness levels and provide excellent penetration rates, while PDC bits offer superior wear resistance and longevity.

Operational Considerations

When selecting a drill bit, operational parameters also play a significant role. Factors such as weight on bit, rotation speed, and mud properties can influence drilling performance. For instance, in soft formations, applying excessive weight on the bit can lead to rapid wear and increased energy consumption. Therefore, operators must adjust these parameters according to the specific geological conditions to optimize bit performance.

Temperature Effects on Bit Selection

Temperature also plays a crucial role in bit selection. High temperatures can affect the material properties of the bit. For example, certain materials may soften, leading to increased wear. In such cases, selecting bits with higher thermal resistance, such as those made from advanced ceramics or specialized alloys, is essential. Similarly, low temperatures can cause brittleness in some materials, necessitating the use of impact-resistant bits.

Field Experience and Case Studies

Field experience provides valuable insights into effective bit selection. Operators who have faced challenging geological conditions often share their insights on which bit types performed best in specific scenarios. For instance, a case study in a shale formation demonstrated that using a combination of PDC bits and roller cone bits resulted in improved drilling rates and reduced costs. Operators noted that adjusting the weight on the bit and rotation speed based on real-time feedback further enhanced performance.

Conclusion

Selecting the appropriate drill bit for different geological environments is critical for optimizing drilling performance and efficiency. By understanding geological conditions, considering the types of bits available, and adjusting operational parameters, operators can enhance their drilling operations significantly. In an ever-evolving industry, making informed decisions based on these criteria is essential for success.