Introduction

Shale gas has become a vital energy resource globally. The use of PDC bits in shale gas drilling offers significant advantages over traditional drilling methods. This article explores the benefits of PDC bits in shale gas applications and discusses potential improvements to enhance their performance.

Key Advantages of PDC Bits

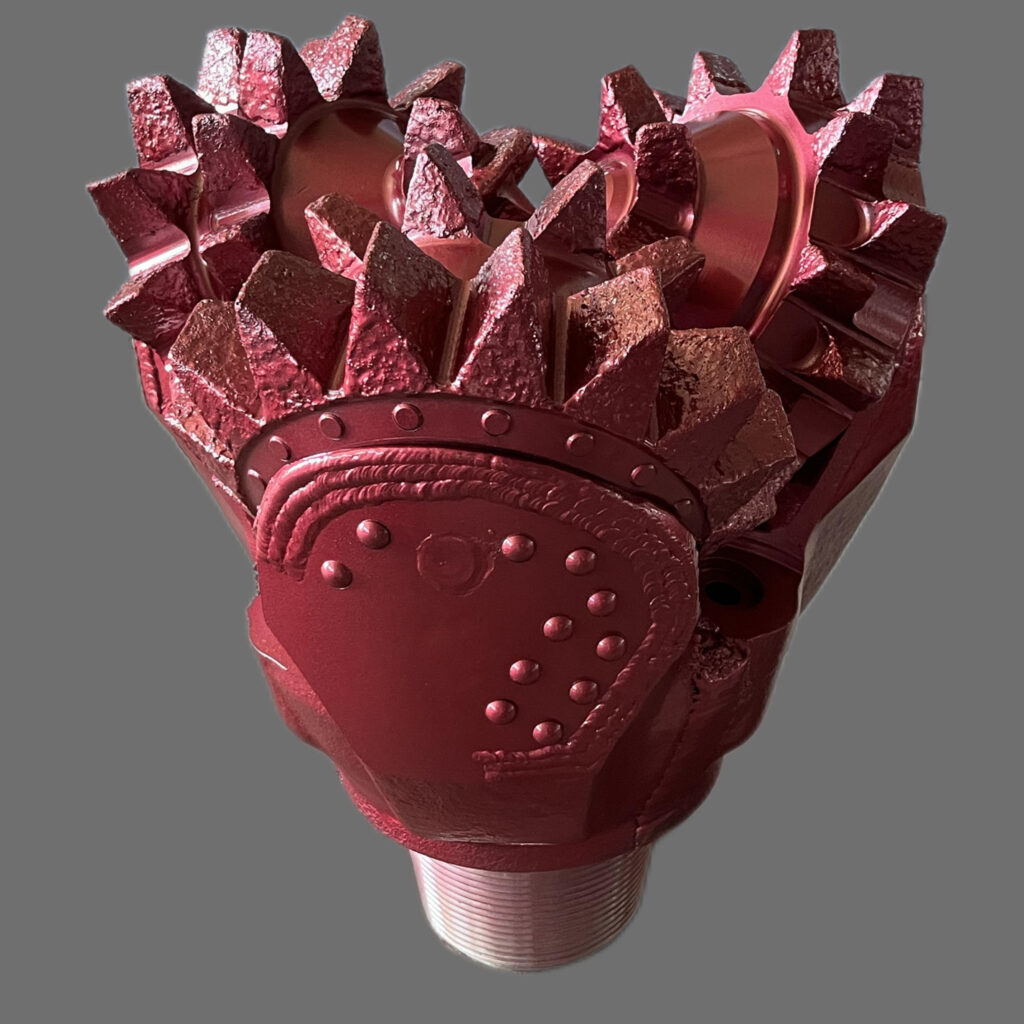

PDC bits are known for their superior cutting efficiency and longevity. In shale formations, they can maintain high penetration rates, reducing overall drilling time. Their ability to cut through varying rock strengths without frequent changes in drilling parameters enhances operational efficiency. Moreover, PDC bits generate less vibration, leading to improved wellbore stability and reduced risk of damage.

Challenges in Shale Gas Drilling

Despite their advantages, PDC bits face challenges in shale gas drilling. The heterogeneous nature of shale formations can lead to unpredictable drilling conditions. Abrasive minerals present in shale can accelerate wear, necessitating frequent bit replacements. Additionally, the presence of natural fractures can complicate drilling and increase the risk of bit damage.

Material Enhancements for PDC Bits

To address wear issues, advancements in materials are crucial. Enhanced diamond coatings can improve the wear resistance of PDC bits, allowing them to withstand the abrasive conditions found in shale formations. Research into nanostructured materials also shows promise in increasing durability and cutting performance. These improvements can extend the life of PDC bits, reducing costs associated with bit replacements.

Optimizing Drilling Parameters

Optimizing drilling parameters is essential for maximizing the performance of PDC bits in shale gas applications. Factors such as weight on bit, rotation speed, and mud properties should be carefully calibrated. Utilizing real-time data analysis can help operators adjust these parameters dynamically, ensuring optimal drilling conditions. This approach can significantly improve penetration rates and reduce wear.

Field Success Stories

Numerous field trials have demonstrated the effectiveness of PDC bits in shale gas drilling. Operators have reported significant reductions in drilling time and costs when employing advanced PDC bits. For example, in the Barnett Shale, companies using optimized PDC bits achieved a 30% increase in drilling efficiency. These success stories underscore the value of continuous innovation in bit technology.

Conclusion

PDC bits provide significant advantages in shale gas drilling, including improved efficiency and durability. However, addressing challenges such as wear and unpredictable formation conditions is crucial. By focusing on material advancements and optimizing drilling parameters, the performance of PDC bits can be further enhanced. Continuous innovation will drive the future of shale gas drilling, ensuring reliable and efficient operations.