Introduction

Ultra-deep well drilling presents unique challenges due to extreme depths and harsh environments. PDC bits have become essential tools for such operations. This article explores the applications of PDC bits in ultra-deep wells and discusses the challenges faced in these environments.

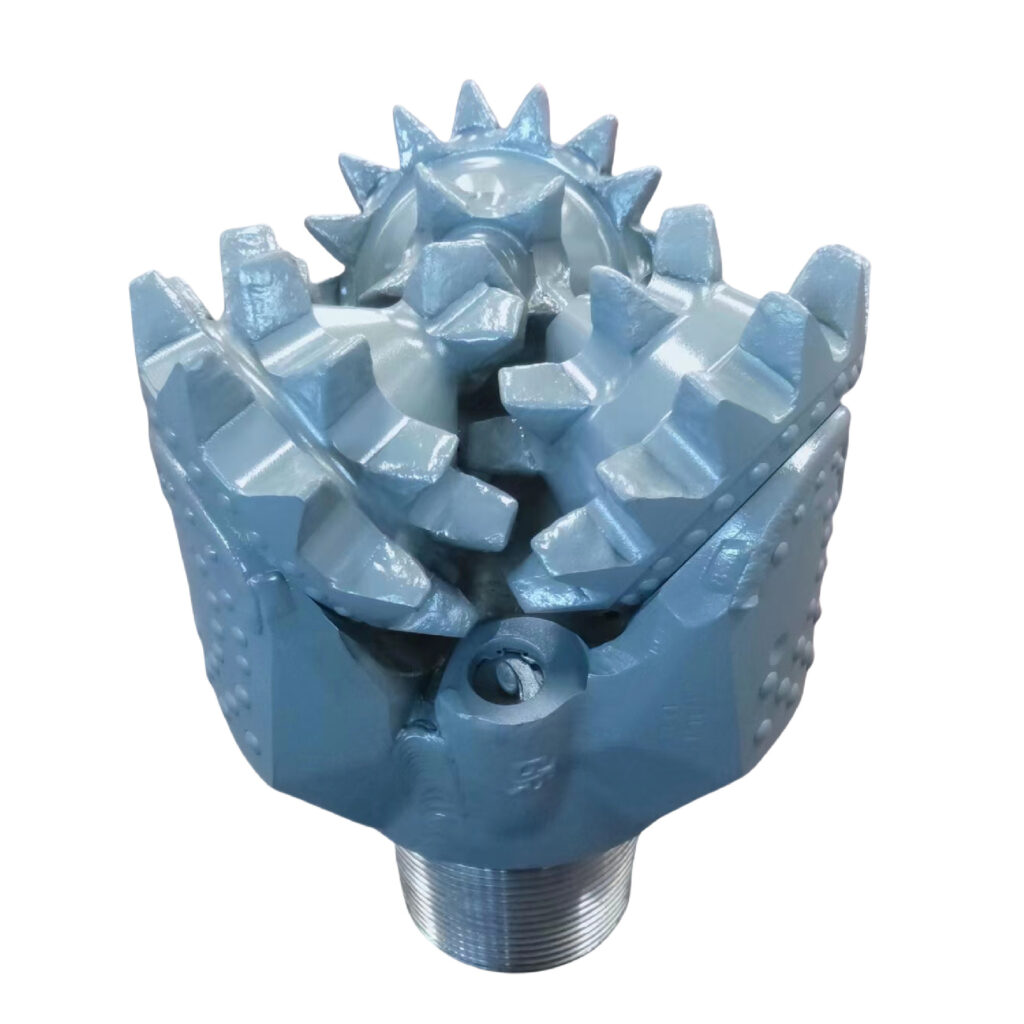

Key Applications of PDC Bits

PDC bits are preferred for ultra-deep well drilling due to their efficiency and durability. They excel in hard rock formations and can maintain high penetration rates. In oil and gas exploration, PDC bits are used to reach deep reservoirs that conventional bits cannot access. Their ability to drill through tough formations while minimizing downtime makes them invaluable in these applications.

Challenges in Ultra-Deep Well Drilling

Drilling at extreme depths introduces several challenges. High temperature and pressure can affect the performance of PDC bits. Thermal degradation of materials may occur, leading to reduced durability. Additionally, the presence of abrasive formations can accelerate wear. Effective cooling and lubrication techniques are crucial to mitigate these issues and extend bit life.

Material Innovations for PDC Bits

To address the challenges faced in ultra-deep well drilling, advancements in materials are essential. New composite materials and coatings can enhance the heat and wear resistance of PDC bits. Research into novel diamond composites offers improved performance in extreme conditions. These innovations help ensure that PDC bits can withstand the rigors of ultra-deep drilling operations.

Advanced Drilling Techniques

Utilizing advanced drilling techniques is crucial for the successful application of PDC bits in ultra-deep wells. Techniques such as managed pressure drilling (MPD) allow for better control of the wellbore environment. This control helps prevent issues like blowouts and stuck pipes. Additionally, automated drilling systems can optimize drilling parameters in real time, enhancing overall efficiency.

Field Case Studies

Several field case studies demonstrate the effectiveness of PDC bits in ultra-deep well drilling. For instance, operators in the Gulf of Mexico have reported significant reductions in drilling time and costs when using advanced PDC bits. These case studies highlight the importance of continuous innovation and adaptation to meet the unique challenges of ultra-deep drilling.

Conclusion

PDC bits are indispensable in ultra-deep well drilling, providing efficiency and durability. However, they face unique challenges that require ongoing innovation in materials and techniques. By addressing these challenges, the drilling industry can continue to explore deep reservoirs and enhance overall productivity. The future of ultra-deep well drilling depends on the continued development of advanced PDC bit technologies.