Introduction

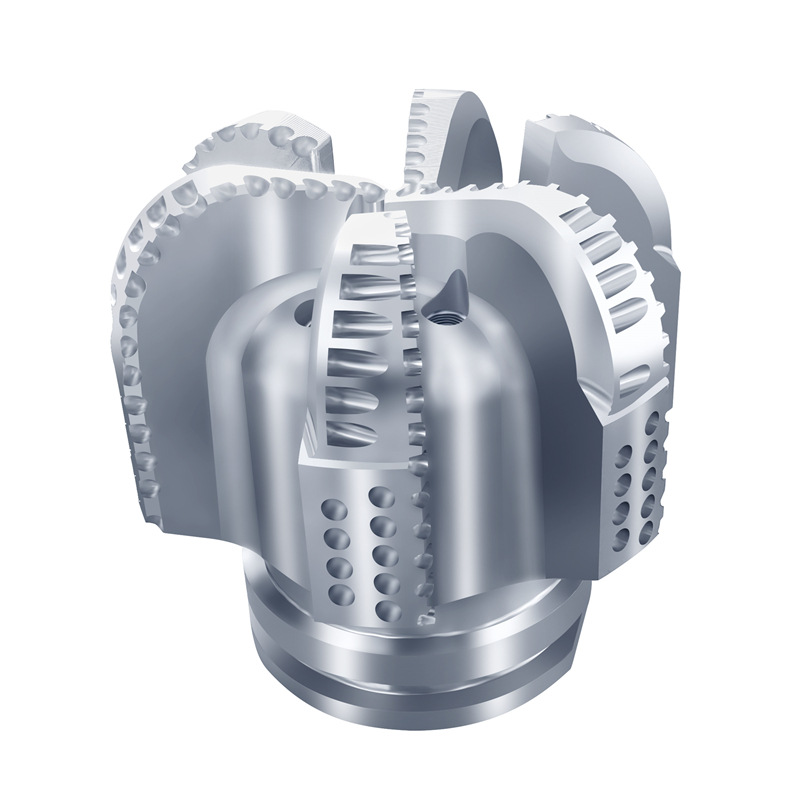

Tricone bits are essential tools in drilling operations, but their performance can degrade due to wear. Monitoring wear is crucial to maintain efficiency and prevent unexpected failures. This article discusses various techniques for wear monitoring and predictive maintenance in tricone bits.

Understanding Wear Mechanisms

Wear in tricone bits can occur through different mechanisms, including abrasion, erosion, and fatigue. Abrasion is common in hard rock formations, where the cutting surfaces wear down over time. Erosion occurs due to high-velocity fluid impacts. Fatigue wear develops from repeated loading and unloading cycles. Understanding these mechanisms helps in selecting appropriate monitoring techniques.

Wear Monitoring Techniques

Several techniques can be employed to monitor wear in tricone bits. Visual inspections can identify visible signs of wear, such as chipped teeth or surface roughness. Acoustic emission monitoring can detect changes in sound patterns that indicate wear. Vibration analysis can also reveal imbalances caused by uneven wear. Each technique has its advantages and can be used in combination for more accurate assessments.

Predictive Maintenance Strategies

Predictive maintenance strategies use wear monitoring data to forecast when maintenance should be performed. Machine learning algorithms can analyze historical wear data to predict future wear patterns. This proactive approach reduces downtime and extends the lifespan of tricone bits. By performing maintenance at the right time, operators can avoid catastrophic failures and optimize drilling efficiency.

Case Studies in Wear Monitoring

Field case studies demonstrate the effectiveness of wear monitoring techniques. For instance, operators using acoustic emission monitoring have reported improved detection of wear-related issues. By implementing predictive maintenance based on wear data, some companies have seen a 20% reduction in drilling costs. These success stories highlight the importance of monitoring and maintenance in optimizing drilling operations.

Future Trends in Wear Monitoring

The future of wear monitoring and predictive maintenance lies in advanced technologies. IoT sensors can provide real-time data on bit performance, enabling continuous monitoring. Big data analytics will enhance predictive maintenance strategies by processing vast amounts of data to identify wear patterns. These advancements will lead to smarter, more efficient drilling operations.

Conclusion

Wear monitoring and predictive maintenance are essential for maximizing the performance of tricone bits. By understanding wear mechanisms and employing effective monitoring techniques, operators can improve efficiency and reduce costs. The integration of advanced technologies will further enhance these strategies, leading to a new era in drilling operations.